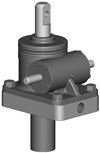

50 Ton Machine Screw Jacks

UL1050, UL2050

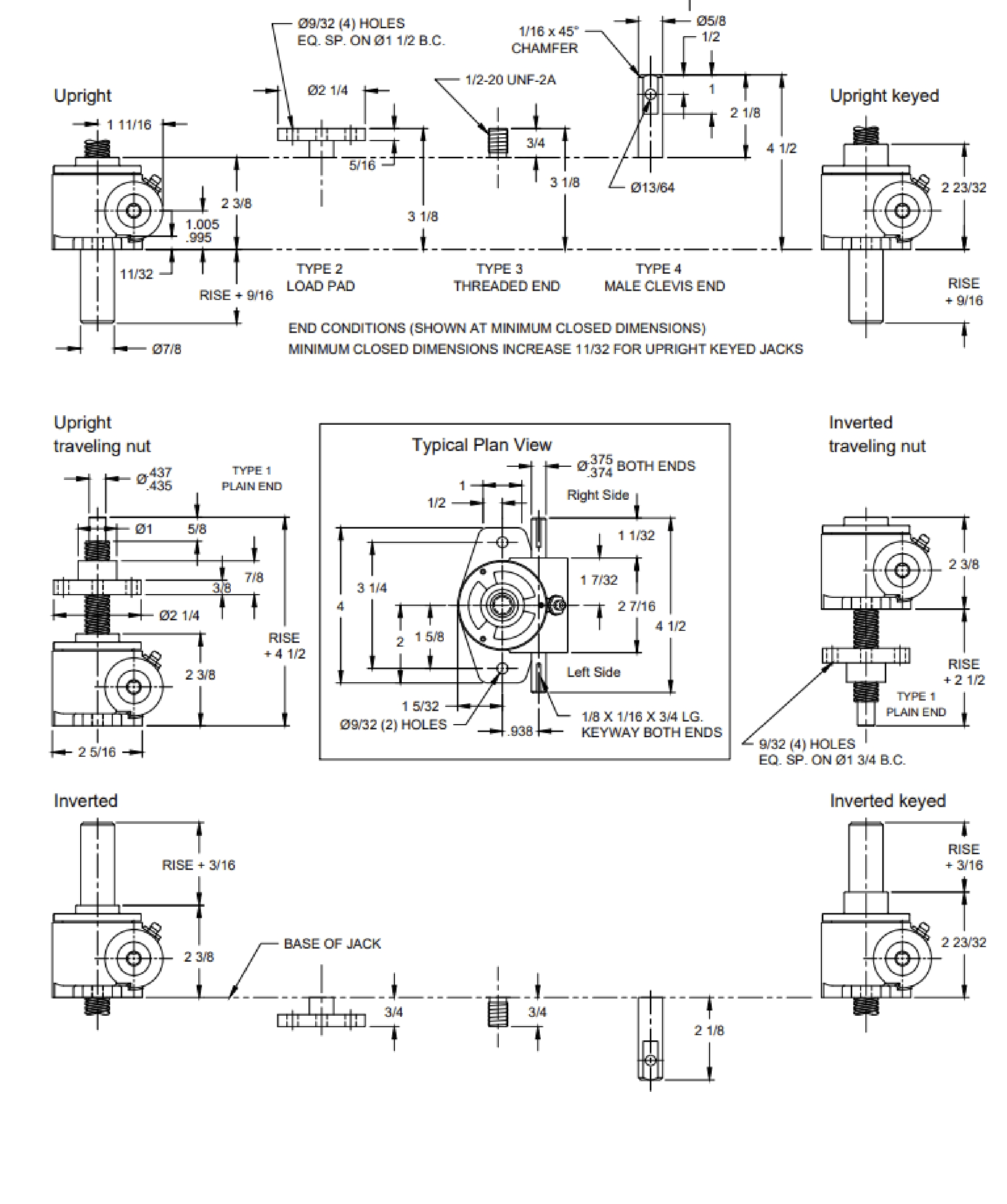

UNI-LIFT series 50 ton machine screw jacks offer precise positioning, uniform lifting speeds and capacity up to 50 Tons. Standard model configurations include upright or inverted units with translating or rotating lifting screws. End configurations include load pad, plain, threaded, and clevis ends.

Contact Joyce for 2D/3D models and drawings:

(937) 294-6261

(800) 523-5204

2D/3D Drawings

Login to access 2D/3D Drawings

Product Media

Available Models

Sample Part Number:

Click on the part number to reveal additional informaton about jack designs and shaft codes.

Model Number

| 1500 Lb | 1 Ton | 2 Ton | 5 Ton | 10 Ton | 20 Ton | 30 Ton | 50 Ton |

|---|---|---|---|---|---|---|---|

| DUL1500 | UL51 | UL62 | UL55 | UL610 | UL820 | UL930 | UL1050 |

| UL1500 | UL101 | UL82 | UL125 | UL1210 | UL1620 | UL1830 | UL2050 |

| UL122 | UL245 |

Jack Configuration

|

|

|

U=Upright |

I=Inverted |

End Conditions

|

|

|

|

|

1=T1 |

2=T2 |

3=T3 |

4=T4 |

Jack Designs

|

|

|

|

|

|

S=Translating |

K=Keyed for Non Rotation |

N=Traveling Nut |

D=Double Clevis |

R=KFTN Trunnion* |

* Standard trunnion mounts available on 2-ton through 20-ton jacks.

Machine Screw Jack Rise

Rise is travel expressed in inches and not the actual screw length.

Left Side Shaft Code |

Right Side Shaft Code |

|

XXXX=Remove |

XXXX=Remove |

Optional Shaft Codes

Screw Stops and Boots

Screw stops are optional on machine screw jacks. When specified, the closed height of the jack and/or the protection tube length may be increased. When boots are added to machine screw jacks, the closed height of the jack may be increased.

Mechanical Counters

CNT0=0.001" Increments

Note: Contact Joyce/Dayton for availability and options.

Hand Wheels

HW04=4" dia

HW06=6" dia

HW08=8" dia

HW10=10" dia

HW12=12" dia

Geared Potentiometers

POTA=0-10V (IP65)

POTB=4-20MA (IP65)

POTC=0-10V w/2 switches*

POTD=4-20MA w/2 switches*

*Optional IP65 rating available

Encoders and Electronic Liit Switches

ENCX=Encoder

ELS2=2 Position Electronic Switch

ELS4=4 Position Electronic Switch

ELS6=6 Position Electronic Switch

Motor for Systems and Direct Drives

- All standard motors are 3-phase, 208-230/460 VAC or 230/460 VAC. Other motor options are available. Specify the appropriate motor size from the chart on the right.

- Refer to the "Additional Options" chart on the preceding page as needed.

- Brake motors (M2) are recommended for jacks that are not self-locking, and jacks with double lead screws.

- If the motor frequency will be varied to provide a "soft" start an inverter duty motor may be required.

Motors

| Size | Code |

|---|---|

| 1/4 HP | K |

| 1/3 HP | A |

| 1/2 HP | B |

| 3/4 HP | C |

| 1 HP | D |

| 1-1/2 HP | E |

| 2 HP | F |

| 3 HP | L |

| 5 HP | G |

| 7-1/2 HP | H |

| 10 HP | I |

| 15 HP | J |

Motor Mounts

Ordering Example:

MMA A (Motor code from chart above)

MMA=56C

MMB=140TC

MMC=180TC

MMD=210TC

Standard motor adapters are aluminum

Mechanical Limit Switches

Ordering Example:

LA (Models) 1(Number of DPDT Switches) 3(Available Positions)

| Model | Code | Available Positions | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LS7-402 | LI |

Number of DPDT Switches NOTE: Will always be 0 for LS7 models |

1 | 2* | 3 | 4 | 5 | 6* | 7 | 8 | |

| LS8-402 | LA | Left Side Shaft Options |  |

|

|

|

|

|

|

|

|

| LS8-504 | LB | ||||||||||

| LS9-502 | LC | ||||||||||

| LS9-503 | LD | Right Side Shaft Options |  |

|

|

|

|

|

|

|

|

| LS9-504 | LE | ||||||||||

| LS9-505 | LF | ||||||||||

| LS9-506 | LG |

*These positions are not standard. Contact Joyce/Dayton with your requirements. |

|||||||||

| LS9-507 | LH | ||||||||||

Additional Options

- X=Standard Jack, no additional options

- S=Additional Specification Required (comment as necessary)

Anti-Backlash

- A=Split Nut

- A90=A90 Design

- A95=A95 Design

Protective Boots

- B=Protective Boot

- D=Dual Protective Boot

Finishes

- F1=Do Not Paint

- F2=Epoxy Paint

- F3=Outdoor Paint Process

Motor Options

- M1=Less Motor

- M2=Brake Motor

- M3=Single Phase Motor (120VAC)

- M4=50Hz Motor

Grease/Seals

- H1=High Temperature Operation

- H2=Food Grade

Screw Stops

- ST0=Extending

- ST1=Retracting

- ST2=Both

- Specify as many options as needed

| Model | Capacity | Screw Diameter (inches) | Thread Pitch/Lead | Worm Gear Ratio | Worm Shaft Turns for 1" Travel | Tare Torque (Inch Lbs.) | Starting Torque (Inch Lbs.) | Operating Torque (Inch Lbs.) | Efficiency Rating % Approx | Screw Torque (Inch Lbs.) | Basic Jack Weight (Lbs.) | Jack Weight per Inch Travel (Lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DUL1500 | 1500 Pound | 0.625 | .125/.25 | 5:1 | 20 | 1 | 0.030W* | 0.022W* @500 RPM | 52.8 | 0.087W* | 2 | 0.1 |

| UL1500 | 1500 Pound | 0.625 | 0.125 | 5:1 | 40 | 2 | 0.024W* | 0.016W* @500 RPM | 37.5 | 0.065W* | 2 | 0.1 |

| UL51 | 1 Ton | 0.750 | 0.25 | 5:1 | 20 | 3 | 0.034W* | 0.023W* @500 RPM | 50.2 | 0.098W* | 9 | 0.2 |

| UL101 | 1 Ton | 0.750 | 0.25 | 10:1 | 40 | 3 | 0.021W* | 0.014W* @500 RPM | 41.1 | 0.098W* | 9 | 0.2 |

| UL62 | 2 Ton | 1.000 | 0.25 | 6:1 | 24 | 4 | 0.035W* | 0.022W* @500 RPM | 43.3 | 0.120W* | 13 | 0.4 |

| UL82 | 2 Ton | 1.000 | 0.25 | 8:1 | 32 | 4 | 0.029W* | 0.018W* @500 RPM | 40.1 | 0.120W* | 13 | 0.4 |

| UL122 | 2 Ton | 1.000 | 0.25 | 12:1 | 48 | 4 | 0.023W* | 0.014W* @500 RPM | 34.1 | 0.120W* | 13 | 0.4 |

| UL55 | 5 Ton | 1.500 | 0.333 | 5:1 | 16 | 5 | 0.052W* | 0.034W* @300 RPM | 44.7 | 0.175W* | 23 | 0.7 |

| UL125 | 5 Ton | 1.500 | 0.333 | 12:1 | 36 | 5 | 0.032W* | 0.019W* @300 RPM | 30.5 | 0.175W* | 23 | 0.7 |

| UL245 | 5 Ton | 1.500 | 0.333 | 24:1 | 72 | 5 | 0.024W* | 0.013W* @300 RPM | 15.7 | 0.175W* | 23 | 0.7 |

| UL610 | 10 Ton | 1.750 | 0.333 | 6:1 | 18 | 7 | 0.055W* | 0.035W* @200 RPM | 35.3 | 0.197W* | 47 | 0.9 |

| UL1210 | 10 Ton | 1.750 | 0.333 | 12:1 | 36 | 7 | 0.036W* | 0.021W* @200 RPM | 26.5 | 0.197W* | 47 | 0.9 |

| UL820 | 20 Ton | 2.500 | 0.500 | 8:1 | 16 | 9 | 0.060W* | 0.038W* @200 RPM | 36.4 | 0.285W* | 90 | 1.8 |

| UL1620 | 20 Ton | 2.500 | 0.500 | 16:1 | 32 | 9 | 0.039W* | 0.023W* @200 RPM | 27.4 | 0.285W* | 90 | 1.8 |

| UL930 | 30 Ton | 2.750 | 0.5 | 9:1 | 18 | 10 | 0.057W* | 0.035W* @200 RPM | 34.4 | 0.307W* | 103 | 2.1 |

| UL1830 | 30 Ton | 2.750 | 0.5 | 18:1 | 36 | 10 | 0.037W* | 0.022W* @200 RPM | 25.8 | 0.307W* | 103 | 2.1 |

| UL1050 | 50 Ton | 4.250 | 0.667 | 10:1 | 15 | 12 | 0.076W* | 0.046W* @150 RPM | 31.4 | 0.463W* | 230 | 5 |

| UL2050 | 50 Ton | 4.250 | 0.667 | 20:1 | 30 | 12 | 0.049W* | 0.029W* @150 RPM | 23.5 | 0.463W* | 230 | 5 |