Stainless Steel Screw Jacks

About Stainless Screw Jacks

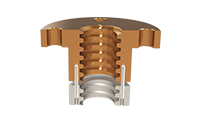

Joyce stainless steel screw jacks are specifically designed for positioning and lifting applications that are located in wet, corrosive and harsh environments. Metallurgical properties of stainless steel allow it to remain ductile even at very low temperatures. These mechanical jacks are available in 2 ton through 25 ton capacities. Upright or inverted jacks operate at full capacity in tension or compression.

- All exposed surfaces and components feature stainless steel or bronze construction

- Nitrile rubber seals protect all internal mechanisms.

- Tapered or ball thrust bearings provide rugged reliability

- Choose one of four standard end conditions

- Protective boots available

- Anti-backlash devices available

- Joyce/Dayton can customize to your specifications

- Custom finishes available

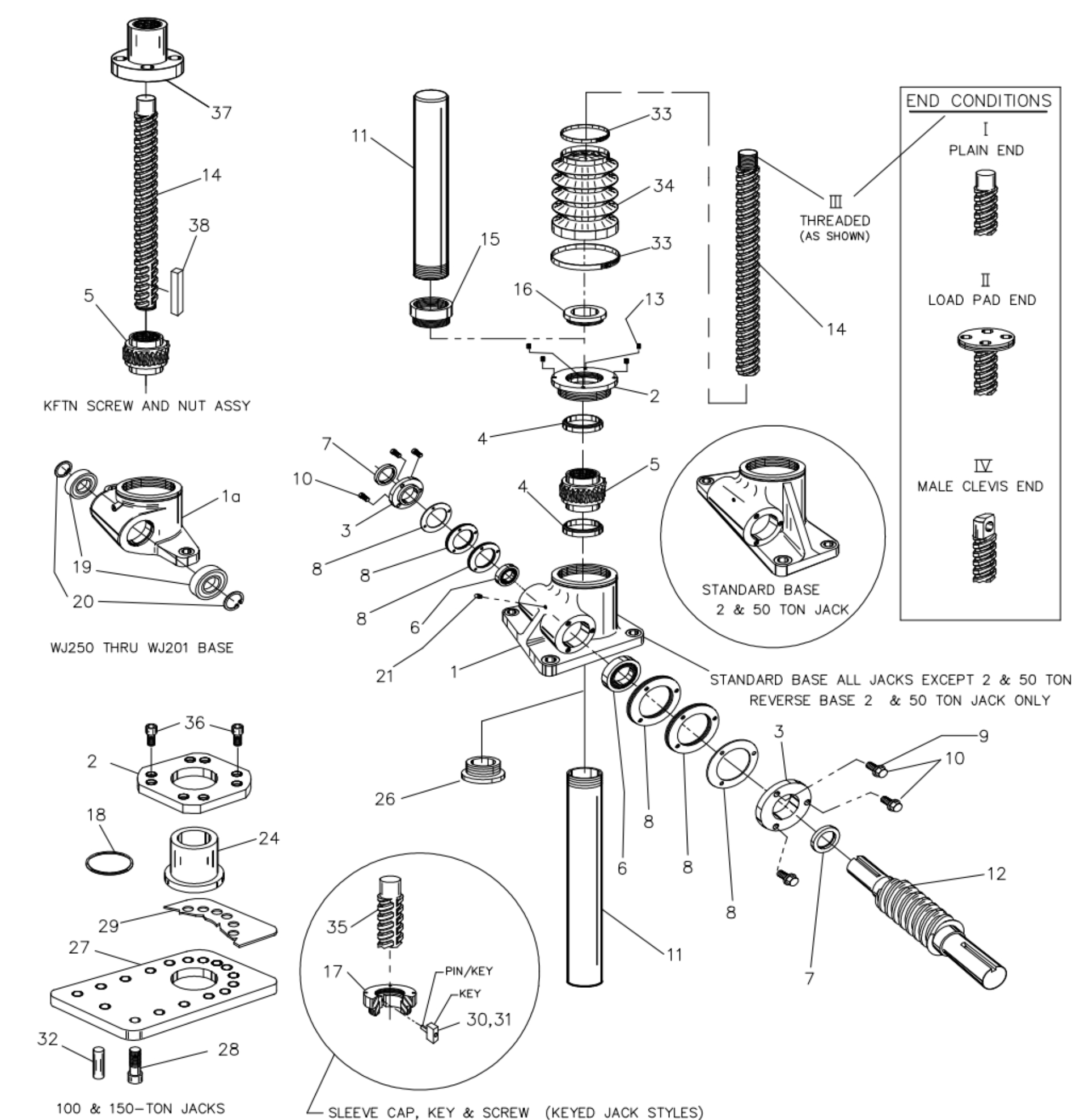

Parts list and exploded views are included in the O&M Manual. Serial numbers are attached to the product housing.

Joyce/Dayton provides motor controls ranging from simple Motor Starters to complex positioning systems and Custom controls. Every system that is powered by an electric motor requires a control system. At Joyce, we know that choosing the best option can sometimes be a challenge. That’s why our Engineers are available to help you through the process.

Product Media

Available Models

Joyce/Dayton provides motor controls ranging from simple Motor Starters to complex positioning systems and Custom controls. Every system that is powered by an electric motor requires a control system. At Joyce, we know that choosing the best option can sometimes be a challenge. That’s why our Engineers are available to help you through the process.

Boots and special finishes are available for Joyce Ball Screw Jacks. Choose from a variety of boot materials and designs for the jacks you select(translating or KFTN). Joyce offers premium finishes, outdoor paint process, and custom finishes to meet your specifications. We have a hassle-free process for delivering what you need.

What you need to know to specify Motorized Ball Screw ComDRIVE jacks in industrial application.

Travel speeds and load capacities of standard ComDRIVE jacks are listed in the catalog. Here are a few tips.

- Select the best option from the chart based on your load and speed.

- Remember the charted load is based on a single ComDRIVE. If you pair a ComDRIVE with a jack, choose a motor that can lift the total system load.

- High-lead ComDrives can achieve faster travel speeds than their standard-lead counterparts. High-lead part numbers begin with "H" (HWB62, HWB245, etc.).

- Standard ComDRIVES use 1750 RPM, 3 phase, 60 HZ motors but we can supply whatever you need.

- Brake motors are needed to hold position.

- When you buy a ComDRIVE with a companipon jack, Joyce will deliver a matched jack(s) with the same closed height.

- Larger capacity ComDRIVES are available upon request. Let us know what you need.

Ball Screw Jacks are rated based on their static thrust capacity from 1-ton to 50-tons. But the selection of the best jack for the application requires further consideration.

- When jacks are loaded in compression one must consider the load carrying capacity of the lifting screw (column load). How high do you need to lift the load? Choose a jack whose lifting screw is stout enough to handle the load at full rise.

- Consider the travel speed of the DYNAMIC load. The speed at which the load will be moved is a limiting factor. How fast do you need to move the load? Sometimes high lead ball screw jacks or bevel ball actuators are a better choice in a given application.

- How frequently will the jack need to move the load? Ball screw jacks are much more efficient than machine screw jacks, so heat is less of a factor in their operation, yet cycles for ball screw jacks must include some periods of rest.

- You can choose a ball screw jack that meets specific life requirements. A calculated ball nut life (in inches) can be established for ball screw jacks based on the load, and duty cycle. Use the JAX® Online software to determine this.

Once loads, duty cycles, and travel speeds are established, designers must select which jack design to use.

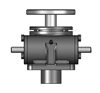

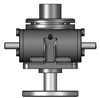

- Translating Design Jacks are most often selected. With this design, a driven input worm acts on an internal worm gear causing the lifting screw to extend or retract. Operation requires that rotation of the lifting screw be prevented. This rotation it restrained whenever two or more jacks are tied to the same load.

- Ball screw jacks cannot be keyed for non-rotation the same way that machine screw jacks are keyed. Contact Joyce for a design solution if you need a keyed ball screw jack.

- Keyed for Traveling Nut Design (KFTN) jacks are another option. These jacks have a fixed length lifting screw that rotates. Loads are attached to a flanged “traveling” ball nut that translates up and down the length of the rotating screw. This type of jack is ideal for applications that cannot accommodate a screw protection tube or that require a flush mount

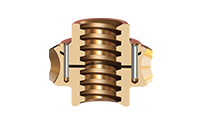

Special features inherent in wormgear ball screw jacks.

Ball screw jacks include ball nuts that are about 90% efficient so the jacks require much less energy to lift an equal load than their machine screw jack counterpart. They are NOT self-locking so a brake motor needs to be included in the drive system and hand wheels are not a recommended option.

Take the work out of using screw jacks in systems

Tell us what you need or use our exclusive JAX® Online software (it’s free). We will put together complete systems with single or multiple screw jacks for you. The software is great because it calculates motor horsepower and shaft diameters and torques. There are several common arrangements, but the program is flexible and allows you to design what you need..

Where are worm gear ball screw jacks used?

Motorized worm gear ball screw jacks are fast and efficient. They can accurately position and hold loads up to 50-tons. Examples include: Platform lifts, Damper adjustments, Ergonomic lifts, Maintenance lifts, Roll adjustments, Earth Station Antennas, Solar Trackers, Conveyor adjustments, Packaging equipment, and Gate adjustments.

Anti-backlash Devices

- Available for machine screw jacks

- Available for metric (trapezoidal) jacks

- Limits lifting screw endplay

- Anti-backlash Devices

Encoders

- Standard 200 or 1024 PPR

- Quadrature wave form

- Stainless steel encoder

- Absolute encoder

- Encoders

Follower Nuts

- For KFTN jack

- For translating jack

Input Shaft (worm)

- Square or hex to fit tool

- Special lengths

- 17-4 stainless steel available

- Metric diameters available

- One side can be cut off

- Other modifications available

- Input shaft cover available

Limit Switches

- Rotary cam (2-4 switches)

- SPDT standard

- DPDT available

- Explosion proof available

- Limit Switches

Lubrication

- Standard grease temperature range (40°F to 220°F)

- Low temperature option

- High temperature option

- Food grade option

Machine Screws

- Right hand thread standard

- Left hand thread available on many models

- Special material available

- Special pitch/lead available

- Special finishes available

- Special machining options

- Special end conditions available

Motor Mounts

- NEMA mounts available on 2-ton to 20-ton wormgear jacks and electric cylinders

- NEMA mounts included on integrated actuators

- Servo motor mounts available on 2-ton to 10-ton jacks and electric cylinders, special mounts available

- Custom mounts available

- Motor Mounts and Stock Motors

Potentiometers

- 0-10V (POTA)

- 4-20mA (POTB)

- 0-10V with limit switches (POTC)

- 4-20mA with limit switches(POTD)

- IP65

- Potentiometers

Protective Boots

- Protection from dirt and dust

- Guard against moisture

- Guard against corrosive contaminants

- Neoprene coated nylon (std)

- Special materials available

- Boot Material Chart

- Protective Boots

Screw Stops

- Standard on ComDRIVEs

- Adjustable

- Bolt- on

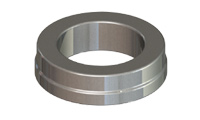

Thrust Rings

- Used in applications where static loads exceed jack capacity

Wormgear Sets

- Right hand gear set standard

- Left hand available on many models

- 25:1 ratio option available on several models

Sample Part Number:

Click on the part number to reveal additional informaton about jack designs and shaft codes.

Model Number

| 2-Ton | 2-Ton Reverse Base | 5-Ton | 10-Ton | 15-Ton | 20-Ton | 25-Ton |

|---|---|---|---|---|---|---|

| SWJ62 SWJ122 SWJ242 |

RSWJ62 RSWJ122 RSWJ242 |

SWJ65 SWJ125 SWJ245 |

SWJ810 SWJ2410 |

SWJ815 SWJ2415 |

SWJ820 SWJ2420 |

SWJ1125 SWJ3225 |

| DSWJ62* DSWJ122* DSWJ242* |

DRSWJ62* DRSWJ122* DRSWJ242* |

DSWJ65* DSWJ125* DSWJ245* |

DSWJ810* DSWJ2410* |

DSWJ815* DSWJ2415* |

DSWJ820* DSWJ2420* |

DSWJ1125* DSWJ3225* |

Important Note: *Not self-locking, may lower under load. Brake motors or external locking systems are recommended.

D: Double Lead Screw

R: Reverse Base Jack, (only available on 2-ton and 50-ton jacks).

Jack Configuration

|

|

|

U=Upright |

I=Inverted |

End Conditions

|

|

|

|

|

1=T1 |

2=T2 |

3=T3 |

4=T4 |

Jack Designs

|

|

|

|

|

|

S=Translating |

K=Keyed for Non Rotation |

N=Traveling Nut |

D=Double Clevis |

R=KFTN Trunnion* |

* Standard trunnion mounts available on 2-ton through 20-ton jacks.

Stainless Steel Jack Rise

Rise is travel expressed in inches and not the actual screw length.

Left Side Shaft Code |

Right Side Shaft Code |

|

XXXX=Remove |

XXXX=Remove |

Optional Shaft Codes

Screw Stops and Boots

Screw stops are optional on stainless steel jacks. When specified, the closed height of the jack and/or the protection tube length may be increased. When boots are added to stainless steel jacks, the closed height of the jack may be increased.

Mechanical Counters

CNT0=0.001" Increments

Note: Contact Joyce/Dayton for availability and options.

Hand Wheels

HW04=4" dia

HW06=6" dia

HW08=8" dia

HW10=10" dia

HW12=12" dia

Geared Potentiometers

POTA=0-10V (IP65)

POTB=4-20MA (IP65)

POTC=0-10V w/2 switches*

POTD=4-20MA w/2 switches*

*Optional IP65 rating available

Encoders and Electronic Limit Switches

ENCX=Encoder

ELS2=2 Position Electronic Switch

ELS4=4 Position Electronic Switch

ELS6=6 Position Electronic Switch

Motor for Systems and Direct Drives

- All standard motors are 3-phase, 208-230/460 VAC or 230/460 VAC. Other motor options are available. Specify the appropriate motor size from the chart on the right.

- Refer to the "Additional Options" chart on the preceding page as needed.

- Brake motors (M2) are recommended for jacks that are not self-locking, and jacks with double lead screws.

- If the motor frequency will be varied to provide a "soft" start an inverter duty motor may be required.

Motors

| Size | Code |

|---|---|

| 1/4 HP | K |

| 1/3 HP | A |

| 1/2 HP | B |

| 3/4 HP | C |

| 1 HP | D |

| 1-1/2 HP | E |

| 2 HP | F |

| 3 HP | L |

| 5 HP | G |

| 7-1/2 HP | H |

| 10 HP | I |

| 15 HP | J |

Motor Mounts

Ordering Example:

MMA A (Motor code from chart above)

MMA=56C

MMB=140TC

MMC=180TC

MMD=210TC

Standard motor adapters are aluminum

Mechanical Limit Switches

Ordering Example:

LA (Models) 1(Number of DPDT Switches) 3(Available Positions)

| Model | Code | Available Positions | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LS7-402 | LI |

Number of DPDT Switches NOTE: Will always be 0 for LS7 models |

1 | 2* | 3 | 4 | 5 | 6* | 7 | 8 | |

| LS8-402 | LA | Left Side Shaft Options |  |

|

|

|

|

|

|

|

|

| LS8-504 | LB | ||||||||||

| LS9-502 | LC | ||||||||||

| LS9-503 | LD | Right Side Shaft Options |  |

|

|

|

|

|

|

|

|

| LS9-504 | LE | ||||||||||

| LS9-505 | LF | ||||||||||

| LS9-506 | LG |

These positions are not standard. Contact Joyce/Dayton with your requirements. |

|||||||||

| LS9-507 | LH | ||||||||||

Additional Options

- X=Standard Jack, no additional options

- S=Additional Specification Required (comment as necessary)

Anti-Backlash

- A=Split Nut

- A90=A90 Design

- A95=A95 Design

Protective Boots

- B=Protective Boot

- D=Dual Protective Boot

Finishes

- F1=Do Not Paint

- F2=Epoxy Paint

- F3=Outdoor Paint Process

Motor Options

- M1=Less Motor

- M2=Brake Motor

- M3=Single Phase Motor (120VAC)

- M4=50Hz Motor

Grease/Seals

- H1=High Temperature Operation

- H2=Food Grade

Screw Stops

- ST0=Extending

- ST1=Retracting

- ST2=Both

- Specify as many options as needed

| Model | Capacity | Screw Diameter (inches) | Thread Pitch/Lead | Worm Gear Ratio | Worm Shaft Turns for 1" Travel | Tare Torque (Inches Lbs.) | Starting Torque (Inches Lbs.) | Operating Torque (Inches Lbs.) | Efficiency Rating % Approx | Screw Torque (Inches Lbs.) | Basic Jack Weight (Lbs.) | Jack Weight per Inch Travel(Lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SWJ62 | 2 ton | 1 | .250 pitch ACME 2C |

6:1 | 24 | 6 | .041W* | .028W* @ 500 RPM |

24.2 | .098W* | 15 | 0.3 |

| SWJ122 | 2 ton | 1 | .250 pitch ACME 2C |

12:1 | 48 | 6 | .025W* | .015W* @ 500 RPM |

22.0 | .098W* | 15 | 0.3 |

| SWJ242 | 2 ton | 1 | .250 pitch ACME 2C |

24:1 | 96 | 6 | .018W* | .009W* @ 500 RPM |

18.3 | .098W* | 15 | 0.3 |

| DSWJ62 | 2 ton | 1 | .250 pitch .500 lead ACME 2C |

6:1 | 12 | 6 | .057W* | .039W* @ 500 RPM |

33.7 | .139W* | 15 | 0.3 |

| DSWJ122 | 2 ton | 1 | .250 pitch .500 lead ACME 2C |

12:1 | 24 | 6 | .035W* | .022W* @ 500 RPM |

30.5 | .139W* | 15 | 0.3 |

| DSWJ242 | 2 ton | 1 | .250 pitch .500 lead ACME 2C |

24:1 | 48 | 6 | .025W* | .013W* @ 500 RPM |

25.4 | .139W* | 15 | 0.3 |

| RSWJ62 | 2 ton | 1 | .250 pitch ACME 2C |

6:1 | 24 | 6 | .041W* | .028W* @ 500 RPM |

24.2 | .098W* | 15 | 0.3 |

| RSWJ122 | 2 ton | 1 | .250 pitch ACME 2C |

12:1 | 48 | 6 | .025W* | .015W* @ 500 RPM |

22.0 | .098W* | 15 | 0.3 |

| RSWJ242 | 2 ton | 1 | .250 pitch ACME 2C |

24:1 | 96 | 6 | .018W* | .009W* @ 500 RPM |

18.3 | .098W* | 15 | 0.3 |

| DRSWJ62 | 2 ton | 1 | .250 pitch .500 lead ACME 2C |

6:1 | 12 | 6 | .057W* | .039W* @ 500 RPM |

33.7 | .139W* | 15 | 0.3 |

| DRSWJ122 | 2 ton | 1 | .250 pitch .500 lead ACME 2C |

12:1 | 24 | 6 | .035W* | .022W* @ 500 RPM |

30.5 | .139W* | 15 | 0.3 |

| DRSWJ242 | 2 ton | 1 | .250 pitch .500 lead ACME 2C |

24:1 | 48 | 6 | .025W* | .013W* @ 500 RPM |

25.4 | .139W* | 15 | 0.3 |

| SWJ65 | 5 ton | 1 1/2 | .375 pitch STUB ACME |

6:1 | 16 | 15 | .065W* | .044W* @ 300 RPM |

23 | .151W* | 32 | 0.7 |

| SWJ125 | 5 ton | 1 1/2 | .375 pitch STUB ACME |

12:1 | 32 | 15 | .041W* | .025W* @ 300 RPM |

20.6 | .151W* | 32 | 0.7 |

| SWJ245 | 5 ton | 1 1/2 | .375 pitch STUB ACME |

24:1 | 64 | 15 | .029W* | .015W* @ 300 RPM |

16.7 | .151W* | 32 | 0.7 |

| DSWJ65 | 5 ton | 1 1/2 | .25 pitch ACME |

6:1 | 12 | 15 | .072W* | .050W* @ 300 RPM |

26.8 | .171W* | 32 | 0.7 |

| DSWJ125 | 5 ton | 1 1/2 | .25 pitch ACME |

12:1 | 24 | 15 | .045W* | .028W* @ 300 RPM |

23.9 | .171W* | 32 | 0.7 |

| DSWJ245 | 5 ton | 1 1/2 | .25 pitch ACME |

24:1 | 48 | 15 | .033W* | .017W* @ 300 RPM |

19.6 | .171W* | 32 | 0.7 |

| SWJ810 | 10 ton | 2 | .500 pitch ACME 2C |

8:1 | 16 | 30 | .061W* | .043W* @ 200 RPM |

23.1 | .195W* | 43 | 1.3 |

| SWJ2410 | 10 ton | 2 | .500 pitch ACME 2C |

24:1 | 48 | 30 | .030W* | .018W* @ 200 RPM |

18.8 | .195W* | 43 | 1.3 |

| DSWJ810 | 10 ton | 2 | .333 pitch .667 lead ACME 2C |

8:1 | 12 | 30 | .070W* | .062W* @ 200 RPM |

31.9 | .228W* | 43 | 1.3 |

| DSWJ2410 | 10 ton | 2 | .333 pitch .667 lead ACME 2C |

8:1 | 12 | 30 | .070W* | .062W* @ 200 RPM |

31.9 | .228W* | 43 | 1.3 |

| SWJ815 | 15 ton | 2 1/4 | .500 pitch ACME 2C |

8:1 | 16 | 45 | .069W* | .047W* @ 200 RPM |

21.1 | .210W* | 59 | 1.4 |

| SWJ2415 | 15 ton | 2 1/4 | .500 pitch ACME 2C |

24:1 | 48 | 45 | .036W* | .020W* @ 200 RPM |

16.6 | .210W* | 59 | 1.4 |

| DSWJ815 | 15 ton | 2 1/4 | .333 pitch .667 lead ACME 2C |

8:1 | 12 | 45 | .079W* | .058W* @ 200 RPM |

34.4 | .244W* | 59 | 1.4 |

| DSWJ2415 | 15 ton | 2 1/4 | .333 pitch .667 lead ACME 2C |

24:1 | 36 | 45 | .041W* | .025W* @ 200 RPM |

27 | .244W* | 59 | 1.4 |

| SWJ820 | 20 ton | 2 1/4 | .500 pitch ACME 2C |

8:1 | 16 | 60 | .075W* | .051W* @ 200 RPM |

19.6 | .277W* | 77 | 1.9 |

| SWJ2420 | 20 ton | 2 1/4 | .500 pitch ACME 2C |

24:1 | 48 | 60 | .039W* | .022W* @ 200 RPM |

15.4 | .277W* | 77 | 1.9 |

| DSWJ820 | 20 ton | 2 1/4 | .375 pitch .750 lead ACME 2C |

8:1 | 10.67 | 60 | .088W* | .061W* @ 200 RPM |

24.5 | .272W* | 77 | 1.9 |

| DSWJ2420 | 20 ton | 2 1/4 | .375 pitch .750 lead ACME 2C |

24:1 | 32 | 60 | .046W* | .026W* @ 200 RPM |

19.3 | .272W* | 77 | 1.9 |

| SWJ1125 | 25 ton | 3 3/8 | .666 pitch STUB ACME |

11:1 | 16 | 75 | .088W* | .055W* @ 200 RPM |

18.3 | .313W* | 164 | 3.1 |

| SWJ3225 | 25 ton | 3 3/8 | .666 pitch STUB ACME |

32:1 | 48 | 75 | .053W* | .025W* @ 200 RPM |

13.5 | .313W* | 164 | 3.1 |

| DSWJ1125 | 25 ton | 3 3/8 | .5625 pitch 1.125 lead ACME 2C |

11:1 | 9.5 | 75 | .106W* | .067W* @ 200 RPM |

25.1 | .384W* | 164 | 3.1 |

| DSWJ3225 | 25 ton | 3 3/8 | .5625 pitch 1.125 lead ACME 2C |

32:1 | 28.5 | 75 | .063W* | .030W* @ 200 RPM |

18.6 | .384W* | 164 | 3.1 |

Important Note: Series DSWJ models may lower under load. Brake motors or external locking systems are recommended.

(R): Reverse Base Jack.

*W: Load in pounds.

Tare Torque: Initial torque to overcome seal and normal assembly drag. This value must be added to starting torque or operating torque values.

Starting Torque: Torque value required to start moving a given load (dissipates to operating torque values once the load begins moving).

Operating Torque: Torque required to continuously raise a given load at the input RPM listed.

Note: If your actual input RPM is 20% higher or lower than the listed RPM, please refer to our JAX® program to determine actual torque values at your RPM.

Screw Torque: Torque required to resist screw rotation (Translating Design Jacks) and traveling nut rotation (Keyed for Traveling Nut Design Jacks).

Lead: The distance traveled axially in one rotation of the lifting screw.

Pitch: The distance from a point on a screw thread to a corresponding point on the next thread, measured axially.