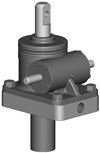

5 Ton Machine Screw Jacks

UL55, UL125, UL245

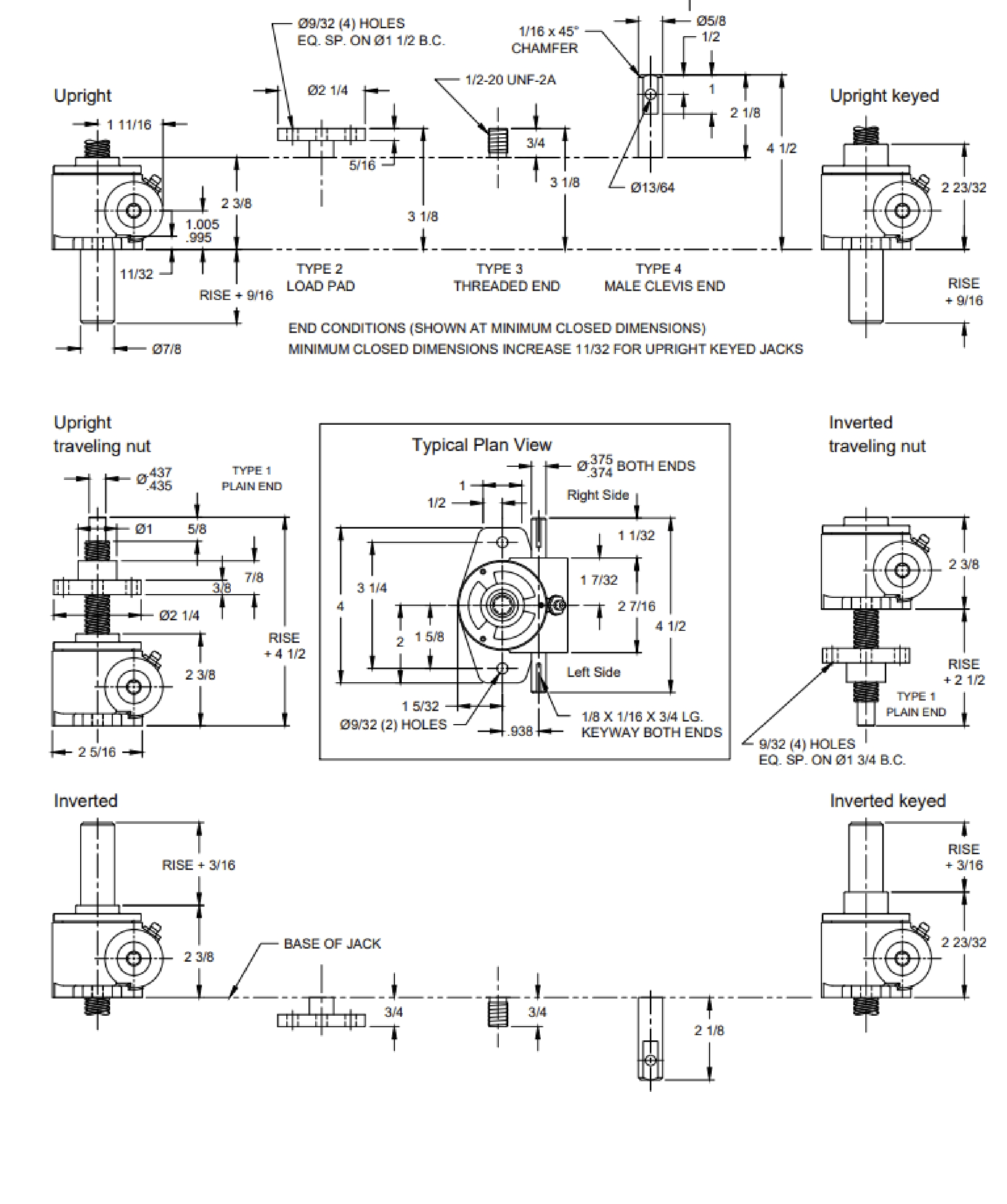

UNI-LIFT series 5 ton machine screw jacks offer precise positioning, uniform lifting speeds and capacity up to 5 Tons. Standard model configurations include upright or inverted units with translating or rotating lifting screws. End configurations include load pad, plain, threaded, and clevis ends.

Contact Joyce for 2D/3D models and drawings:

(937) 294-6261

(800) 523-5204

2D/3D Drawings

Login to access 2D/3D Drawings

Product Media

Available Models

Sample Part Number:

Click on the part number to reveal additional informaton about jack designs and shaft codes.

Model Number

| 1500 Lb | 1 Ton | 2 Ton | 5 Ton | 10 Ton | 20 Ton | 30 Ton | 50 Ton |

|---|---|---|---|---|---|---|---|

| DUL1500 | UL51 | UL62 | UL55 | UL610 | UL820 | UL930 | UL1050 |

| UL1500 | UL101 | UL82 | UL125 | UL1210 | UL1620 | UL1830 | UL2050 |

| UL122 | UL245 |

Jack Configuration

|

|

|

U=Upright |

I=Inverted |

End Conditions

|

|

|

|

|

1=T1 |

2=T2 |

3=T3 |

4=T4 |

Jack Designs

|

|

|

|

|

|

S=Translating |

K=Keyed for Non Rotation |

N=Traveling Nut |

D=Double Clevis |

R=KFTN Trunnion* |

* Standard trunnion mounts available on 2-ton through 20-ton jacks.

Machine Screw Jack Rise

Rise is travel expressed in inches and not the actual screw length.

Left Side Shaft Code |

Right Side Shaft Code |

|

XXXX=Remove |

XXXX=Remove |

Optional Shaft Codes

Screw Stops and Boots

Screw stops are optional on machine screw jacks. When specified, the closed height of the jack and/or the protection tube length may be increased. When boots are added to machine screw jacks, the closed height of the jack may be increased.

Mechanical Counters

CNT0=0.001" Increments

Note: Contact Joyce/Dayton for availability and options.

Hand Wheels

HW04=4" dia

HW06=6" dia

HW08=8" dia

HW10=10" dia

HW12=12" dia

Geared Potentiometers

POTA=0-10V (IP65)

POTB=4-20MA (IP65)

POTC=0-10V w/2 switches*

POTD=4-20MA w/2 switches*

*Optional IP65 rating available

Encoders and Electronic Liit Switches

ENCX=Encoder

ELS2=2 Position Electronic Switch

ELS4=4 Position Electronic Switch

ELS6=6 Position Electronic Switch

Motor for Systems and Direct Drives

- All standard motors are 3-phase, 208-230/460 VAC or 230/460 VAC. Other motor options are available. Specify the appropriate motor size from the chart on the right.

- Refer to the "Additional Options" chart on the preceding page as needed.

- Brake motors (M2) are recommended for jacks that are not self-locking, and jacks with double lead screws.

- If the motor frequency will be varied to provide a "soft" start an inverter duty motor may be required.

Motors

| Size | Code |

|---|---|

| 1/4 HP | K |

| 1/3 HP | A |

| 1/2 HP | B |

| 3/4 HP | C |

| 1 HP | D |

| 1-1/2 HP | E |

| 2 HP | F |

| 3 HP | L |

| 5 HP | G |

| 7-1/2 HP | H |

| 10 HP | I |

| 15 HP | J |

Motor Mounts

Ordering Example:

MMA A (Motor code from chart above)

MMA=56C

MMB=140TC

MMC=180TC

MMD=210TC

Standard motor adapters are aluminum

Mechanical Limit Switches

Ordering Example:

LA (Models) 1(Number of DPDT Switches) 3(Available Positions)

| Model | Code | Available Positions | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LS7-402 | LI |

Number of DPDT Switches NOTE: Will always be 0 for LS7 models |

1 | 2* | 3 | 4 | 5 | 6* | 7 | 8 | |

| LS8-402 | LA | Left Side Shaft Options |  |

|

|

|

|

|

|

|

|

| LS8-504 | LB | ||||||||||

| LS9-502 | LC | ||||||||||

| LS9-503 | LD | Right Side Shaft Options |  |

|

|

|

|

|

|

|

|

| LS9-504 | LE | ||||||||||

| LS9-505 | LF | ||||||||||

| LS9-506 | LG |

*These positions are not standard. Contact Joyce/Dayton with your requirements. |

|||||||||

| LS9-507 | LH | ||||||||||

Additional Options

- X=Standard Jack, no additional options

- S=Additional Specification Required (comment as necessary)

Anti-Backlash

- A=Split Nut

- A90=A90 Design

- A95=A95 Design

Protective Boots

- B=Protective Boot

- D=Dual Protective Boot

Finishes

- F1=Do Not Paint

- F2=Epoxy Paint

- F3=Outdoor Paint Process

Motor Options

- M1=Less Motor

- M2=Brake Motor

- M3=Single Phase Motor (120VAC)

- M4=50Hz Motor

Grease/Seals

- H1=High Temperature Operation

- H2=Food Grade

Screw Stops

- ST0=Extending

- ST1=Retracting

- ST2=Both

- Specify as many options as needed

| Model | Capacity | Screw Diameter (inches) | Thread Pitch/Lead | Worm Gear Ratio | Worm Shaft Turns for 1" Travel | Tare Torque (Inch Lbs.) | Starting Torque (Inch Lbs.) | Operating Torque (Inch Lbs.) | Efficiency Rating % Approx | Screw Torque (Inch Lbs.) | Basic Jack Weight (Lbs.) | Jack Weight per Inch Travel (Lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DUL1500 | 1500 Pound | 0.625 | .125/.25 | 5:1 | 20 | 1 | 0.030W* | 0.022W* @500 RPM | 52.8 | 0.087W* | 2 | 0.1 |

| UL1500 | 1500 Pound | 0.625 | 0.125 | 5:1 | 40 | 2 | 0.024W* | 0.016W* @500 RPM | 37.5 | 0.065W* | 2 | 0.1 |

| UL51 | 1 Ton | 0.750 | 0.25 | 5:1 | 20 | 3 | 0.034W* | 0.023W* @500 RPM | 50.2 | 0.098W* | 9 | 0.2 |

| UL101 | 1 Ton | 0.750 | 0.25 | 10:1 | 40 | 3 | 0.021W* | 0.014W* @500 RPM | 41.1 | 0.098W* | 9 | 0.2 |

| UL62 | 2 Ton | 1.000 | 0.25 | 6:1 | 24 | 4 | 0.035W* | 0.022W* @500 RPM | 43.3 | 0.120W* | 13 | 0.4 |

| UL82 | 2 Ton | 1.000 | 0.25 | 8:1 | 32 | 4 | 0.029W* | 0.018W* @500 RPM | 40.1 | 0.120W* | 13 | 0.4 |

| UL122 | 2 Ton | 1.000 | 0.25 | 12:1 | 48 | 4 | 0.023W* | 0.014W* @500 RPM | 34.1 | 0.120W* | 13 | 0.4 |

| UL55 | 5 Ton | 1.500 | 0.333 | 5:1 | 16 | 5 | 0.052W* | 0.034W* @300 RPM | 44.7 | 0.175W* | 23 | 0.7 |

| UL125 | 5 Ton | 1.500 | 0.333 | 12:1 | 36 | 5 | 0.032W* | 0.019W* @300 RPM | 30.5 | 0.175W* | 23 | 0.7 |

| UL245 | 5 Ton | 1.500 | 0.333 | 24:1 | 72 | 5 | 0.024W* | 0.013W* @300 RPM | 15.7 | 0.175W* | 23 | 0.7 |

| UL610 | 10 Ton | 1.750 | 0.333 | 6:1 | 18 | 7 | 0.055W* | 0.035W* @200 RPM | 35.3 | 0.197W* | 47 | 0.9 |

| UL1210 | 10 Ton | 1.750 | 0.333 | 12:1 | 36 | 7 | 0.036W* | 0.021W* @200 RPM | 26.5 | 0.197W* | 47 | 0.9 |

| UL820 | 20 Ton | 2.500 | 0.500 | 8:1 | 16 | 9 | 0.060W* | 0.038W* @200 RPM | 36.4 | 0.285W* | 90 | 1.8 |

| UL1620 | 20 Ton | 2.500 | 0.500 | 16:1 | 32 | 9 | 0.039W* | 0.023W* @200 RPM | 27.4 | 0.285W* | 90 | 1.8 |

| UL930 | 30 Ton | 2.750 | 0.5 | 9:1 | 18 | 10 | 0.057W* | 0.035W* @200 RPM | 34.4 | 0.307W* | 103 | 2.1 |

| UL1830 | 30 Ton | 2.750 | 0.5 | 18:1 | 36 | 10 | 0.037W* | 0.022W* @200 RPM | 25.8 | 0.307W* | 103 | 2.1 |

| UL1050 | 50 Ton | 4.250 | 0.667 | 10:1 | 15 | 12 | 0.076W* | 0.046W* @150 RPM | 31.4 | 0.463W* | 230 | 5 |

| UL2050 | 50 Ton | 4.250 | 0.667 | 20:1 | 30 | 12 | 0.049W* | 0.029W* @150 RPM | 23.5 | 0.463W* | 230 | 5 |