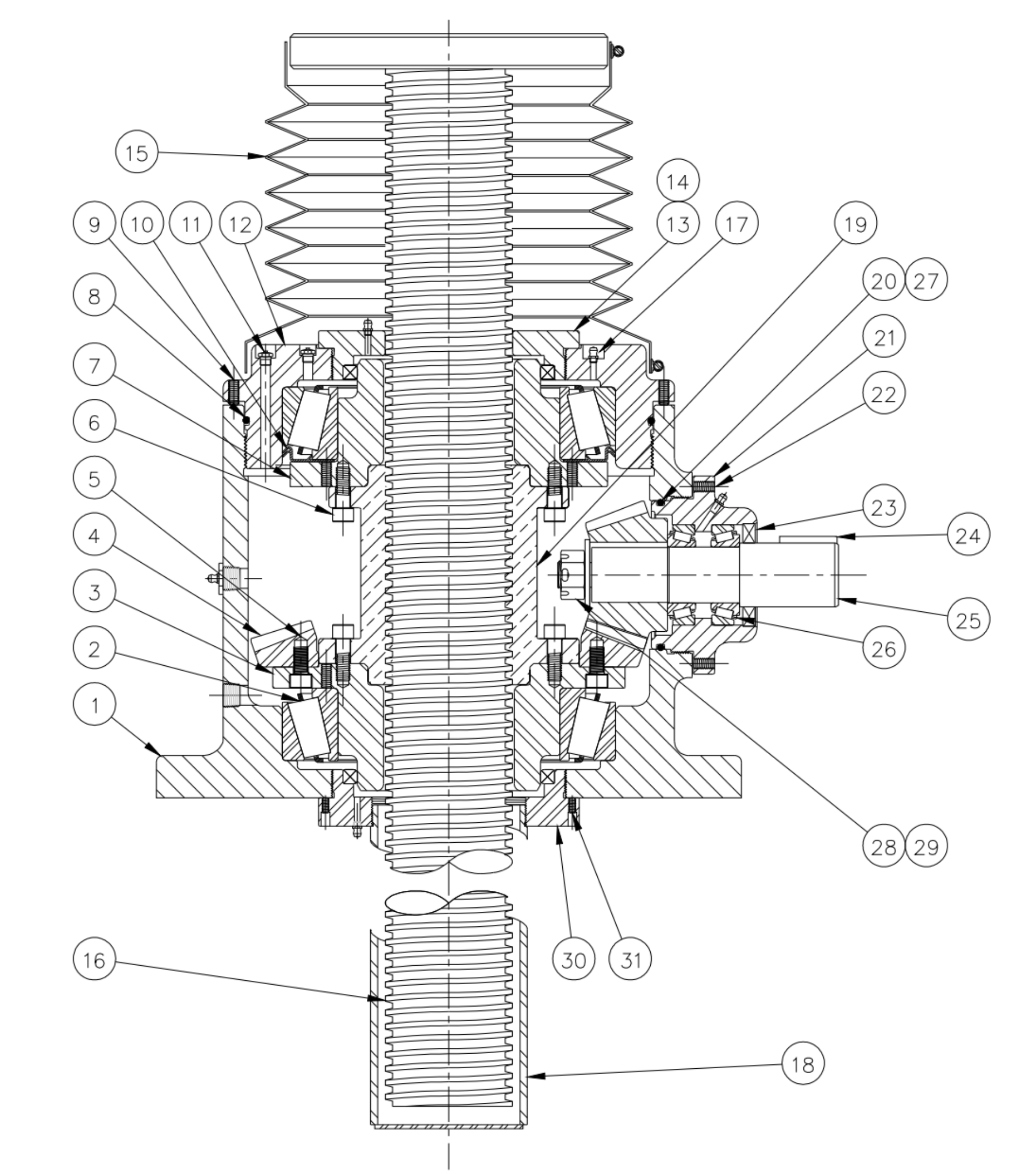

Bevel Gear Jacks

About Bevel Gear Jacks

Joyce Bevel Gear® Jacks, available in 7.5-ton to 100-ton static capacities, offer higher efficiency and greater speed than other mechanical screw jacks. As an added benefit, bevel gear jacks also act as miter boxes, making them an ideal choice for multi-jack systems. As many as three output shafts may be specified for mounting motors, limit switches, readout devices and other accessories. Bevel gear jacks with single lead screws (S series) provide the benefits of a self-locking screw, and bevel gear jacks with double lead screws (D series) offer even greater travel speed.

- Choose one of four standard end conditions

- Protective boots and other options are available

- Right hand and left hand screw threads are available

- Joyce/Dayton can customize to your specifications

Product Media

Joyce offers motor controls ranging from simple Motor Starters to complex positioning systems and Custom controls. Every system that is powered by an electric motor requires a control system. At Joyce, we know that choosing the best option can sometimes be a challenge. That’s why our Engineers are available to help you through the process.

Available Models

Items to consider when selecting motors and mounting configurations:

Use Quick Reference Charts determine the motor horsepower and gear reduction required to reach your target speed. For example, slow travel of just a few inches per minute will require a high ratio electric cylinder paired with a 10:1 ratio external gear reducer. While fast travel up to 546 inches per minute will require a low ratio electric cylinder paired with a direct drive motor.

- Standard model Electric Cylinders are purchased without a motor or external gear reducer.

- Direct Drive models have the motor mounted directly to the input shaft of the Electric Cylinder. The motor extends at a 90 degree angle from eh electric cylinder.

- ComDRIVE models have mounted external gear reducers and motors. The combination of internal and external gear reduction is specified and it accounts for output speed of the specific electric cylinder.

NOTE: Brake motors must be specified for all ballscrews Electric Cylinders (ECB).and for any acme Screw Electric Cylinder (ECA) with an efficiency ratio greater than or equal to 30%.

Smaller Capacity Linear Actuators are available from Joyce:

- Multipurpose Actuators - 1600 lb max. capacity, both AC and DC available, speeds to 96 in./min.

- Integrated Actuators - 2000 lb. max. Capacity, AC, speeds to 345 in./min.

Customization and Special Finishes:

Joyce can customize your Electric Cylinders to meet your requirements.

- Premium external finishes

- Proprietary Outdoor paint process resists corrosive elements and works well in harsh environments.

Encoders

- Standard 200 or 1024 PPR

- Quadrature wave form

- Stainless steel encoder

- Absolute encoder

- Encoders

Finishes

- Enamel finish (standard)

- Epoxy finish

- STEEL IT® epoxy

- Outdoor paint process

- Custom finishes available

- Anodized (250-lb to 1-ton)

- Nickel, Xylan®, Armoloy®

- Finishes

Follower Nuts

- For KFTN jack

- For translating jack

Limit Switches

- Rotary cam (2-4 switches)

- SPDT standard

- DPDT available

- Explosion proof available

- Limit Switches

Lubrication

- Standard grease temperature range (40°F to 220°F)

- Low temperature option

- High temperature option

- Food grade option

Machine Screws

- Right hand thread standard

- Left hand thread available on many models

- Special material available

- Special pitch/lead available

- Special finishes available

- Special machining options

- Special end conditions available

Protective Boots

- Protection from dirt and dust

- Guard against moisture

- Guard against corrosive contaminants

- Neoprene coated nylon (std)

- Special materials available

- Boot Material Chart

- Protective Boots

Screw Stops

- Standard on ComDRIVEs

- Adjustable

- Bolt- on

Sample Part Number:

Click on the part number to reveal additional informaton about jack designs and shaft codes.

Model Number

| Joyce Bevel Gear® Jacks | |

|---|---|

| BG150S | BG1500S |

| BG250S | BG150S |

| BG375S | BG150S |

| BG450S | BG150S |

Jack Configuration

| Jack Configuration | ||

|---|---|---|

|

|

|

| U= Upright | I= Inverted | |

End Conditions

Jack Design

| Actuator Design | ||

|---|---|---|

|

|

|

| S= Translating | Keyed for Non Rotation | N= Travelling Nut |

Bevel Ball Actuator Rise

| Bevel Ball Actuator Rise |

|---|

| Rise is travel expressed in inches and not the actual screw length |

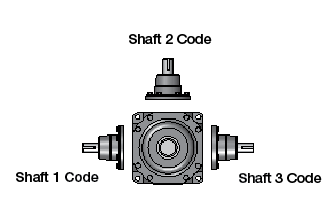

| Shaft Codes |

|---|

| Three shaft codes must be specified for each jack. Electronic and mechanical limit switches may be substituted for the shaft code per the tables on this page. |

| STDX- Standard |

| XXXX- Input shaft no required |

| When ordering with only one input shaft, it is recommended to order the following configuration: XXXX-STDX-XXXX |

Additional Options X= Standard Jack, no additional options X= Additional Specification Required (comment as necessary) Protective Boots B= Protective Boot D= Dual Protective Boot Finishes F1= Do Not Paint F2= Epoxy Paint F3= Outdoor Paint processes ACME Screw L= Left hand Screw Screw Stops ST0=Extending

ST1=Retracting

ST2=Both

| Model | Dynamic Capacity | Upright Assembly: Screw-in compression/ inverted assembly: screw-in tension |

Upright Assembly: screw-in tension/ inverted assembly: Screw-in compression | Screw Dia. | Screw Pitch/Lead | Bevel Gear Ratio | Pinion Turns for 1" Travel | Pinion Torque (In. Lbs.) | Screw Torque | Jack Efficiency | Jack† Cooling Time | Base Weight (Lbs.) | Add for Each Inch of Travel (Lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BG150-S | Please use JAX Software or contact Joyce / Dayton |

14,000 lbs. | 14,000 lbs. | 1 ½" | .375 STUB ACME | 2.69:1 | 7.18 | .059W* | .151W* | 38.5% | 38 min. | 42 | 0.8 |

| BG150-D* | 14,000 lbs. | 14,000 lbs. | 1 ½" | .250P / .500L STUB ACME 2C | 2.69:1 | 5.38 | .066W* | .169W* | 45.6% | 38 min. | 42 | 0.8 | |

| BG250-S | 30,000 lbs. | 30,000 lbs. | 2 ½" | .500P ACME 2C | 2.15:1 | 4.31 | .111W* | .227W* | 34.2% | 82 min. | 140 | 2.6 | |

| BG250-D* | 30,000 lbs. | 30,000 lbs. | 2 ½" | .375P / .750L ACME 2C | 2.15:1 | 2.87 | .133W* | .272W* | 42.6% | 82 min. | 140 | 2.6 | |

| BG375-S | 66,000 lbs. | 40,000 lbs. | 3 ¾" | 666P ACME 2C | 3.52:1 | 5.29 | .098W* | .329W* | 31.5% | 192 min. | 230 | 4.1 | |

| BG375-D* | 66,000 lbs. | 40,000 lbs. | 3 ¾" | .666P / 1.333L STUB ACME | 3.52:1 | 2.64 | .134W* | .448W* | 46.0% | 192 min. | 230 | 4.1 | |

| BG450-S | 218,000 lbs. | 200,000 lbs. | 4 ½" | .500P ACME 2C | 3:1 | 6 | .125W* | .356W* | 21.9% | 262 min. | 650 | 5.5 | |

| BG450-D* | 218,000 lbs. | 200,000 lbs. | 4 ½" | .500P / 1.00L ACME 2C | 3:1 | 3 | .154W* | .438W* | 35.5% | 262 min. | 650 | 5.5 |

Important Note: *Not self-locking, may lower under load. Brake motors or external locking systems are recommended.

D: Double Lead Screws.

S: Single Lead Screws. These jacks are self-locking.

*W: Load in Pounds.

Pinion Torque: The torque required to continuously raise a given load.

Screw Torque: The torque required to resist screw rotation (translating jack design) and traveling nut rotation (keyed for traveling nut design).

Lead: The distance traveled axially in one rotation of the lifting screw.

Pitch: The distance from a point on the screw thread to a corresponding point on the next thread, measured axially.

†: Cooling time based on time to cool from 200°F to 70°F (ambient).