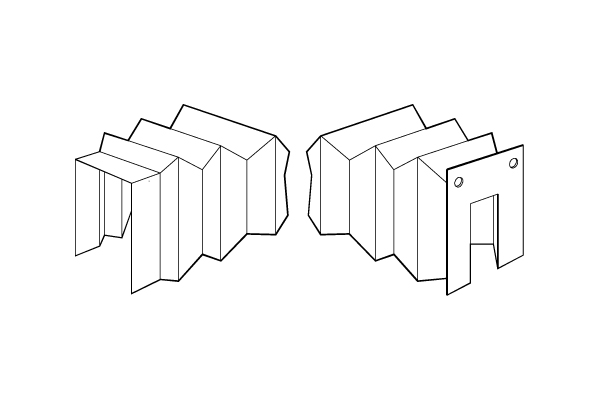

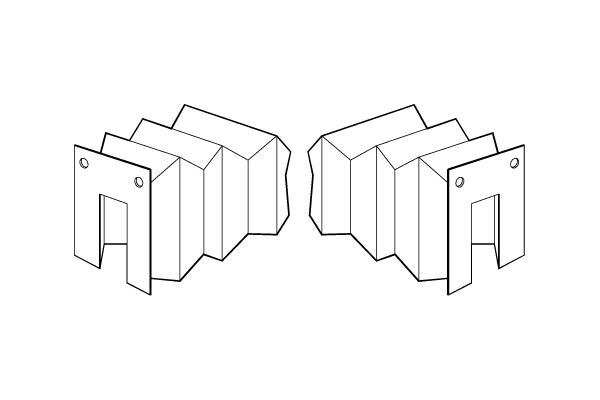

U-Shaped Way Covers

U-Shaped Way Covers

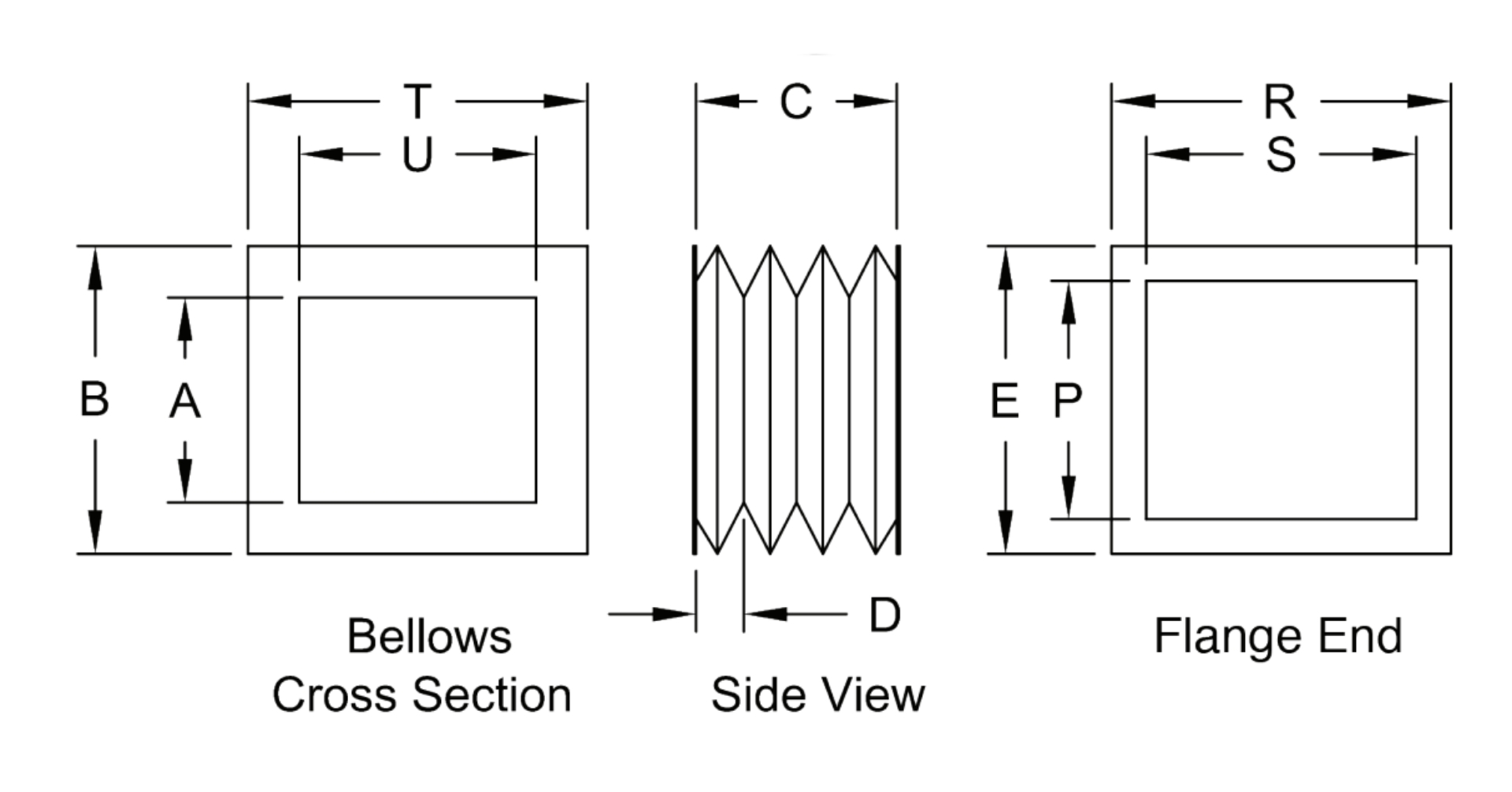

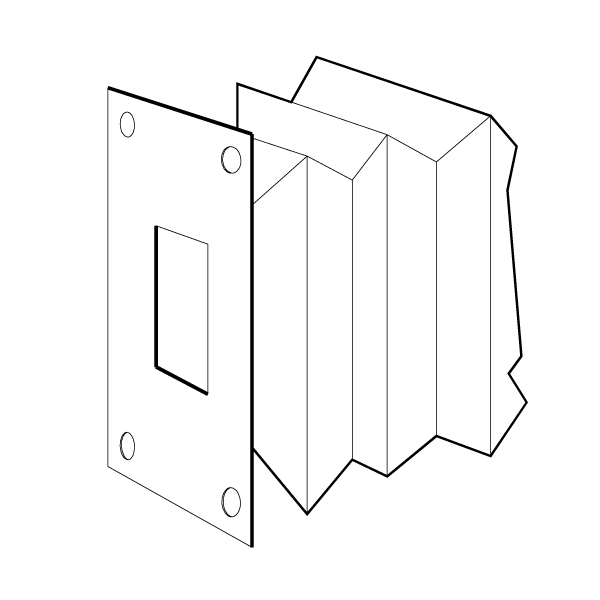

U-shaped covers are frequently used as machine way covers. They are available in almost any size or material to meet different application requirements and environments. Typically they are used to protect machined surfaces from the accumulation of dirt, chips, or other debris. U-shaped covers are normally mounted horizontally over machined surfaces and held in place with flange mounts that fit the mounting hole pattern specified by the customer. Options include Sewn tabs, mounting hole patterns on flange ends, Stiffener guides, and Steel Back Up flanges.

Product Media

Internal Guides

Internal guides are plastic elements used to provide additional stiffness and support to non-vertical bellows. These plastic supports are designed to prevent the bellows from contacting the internal diameter or surface that the bellows protect. Internal guides for round bellows are typically mounted on the inside and may increase the closed dimension of the bellows. Non-circular internal guides are sometimes used to support long horizontal way covers. These guides are fitted between sewn convolutions.

Mounting Hole Pattern in Flange Ends

Customers may specify the mounting hole pattern they need on the sewn fabric flange end of bellows. These mounting holes permit easy installation of bellows onto the customer’s machinery. If added mounting stiffness is required, customers may add as an option, steel back up flanges with coordinating hole patterns.

Sewn Tabs

Sewn tabs are recommended as an option on bellows with long travel lengths. These tabs limit the flexing of individual convolutions and thus stabilize long bellows. They also limit stress to the seams between convolutions. Experienced Customer Service Representatives can help you determine if these sewn tabs would be a benefit for your application.

Steel Back Up Flange

Steel back up flanges are sometimes used in addition to the flange ends of way covers and bellows. These steel flanges provide additional stiffness when mounting bellows and covers to machine elements. Customers may specify a mounting hole pattern to match that of the sewn fabric flange end on the bellows.

| Coating (Col-mdor) | Base Mat'l | Nominal Thickness | Temperature Range | Properties | Limitations |

|---|---|---|---|---|---|

| Neoprene (Black) |

Nylon | .020" (.51 mm) | -60° F to 250° F (-51° C to 121° C) |

Resistant to moderate chemicals, acids, oils, fats, grease and many solvents. Good weathering and physical properties, flame retardant. | Attacked by strong oxidizing acids, esters, ketones, chlorinated aromatic and nitro hydrocarbons. |

| Hypalon (Black or Green) |

Nylon | .023" (.53 mm) to .024" (.61 mm) | -60° F to 300° F (-51° C to 149° C) |

Well suited for use in corrosive chemical environments. Offers additional resistance particularly against oxidizing agents like sulfuric acid, hypachlorites, high ozone, moderate chemicals, acids, oils, fats, grease and many solvents. Good weathering and physical properties, flame retardant. | Attacked by concentrated oxidizing acids, esters, ketones, chlorinated aromatic and nitro hydrocarbons. |

| Aluminum (Silver) |

Fiberglass | .020" (.51 mm) | -100° F to 550° F (-73° C to 288° C) |

Excellent heat resistance and is not combustible. Will not rot or decay. Resistant to many solvents, weather and corrosive vapors. Has a 95% reflective heat property. | Man-made material whose main constitute is silica sand. Begins to melt at 750° F. |

| Silicone (Red) |

Fiberglass | .022" (.55 mm) | -100° F to 450° F (-73° C to 232° C) |

Resistant to moderate or oxidizing chemicals, ozone and concentrated sodium hydroxide. | Attacked by many solvents, oils, concentrated acids and diluted sodium hydroxide. |

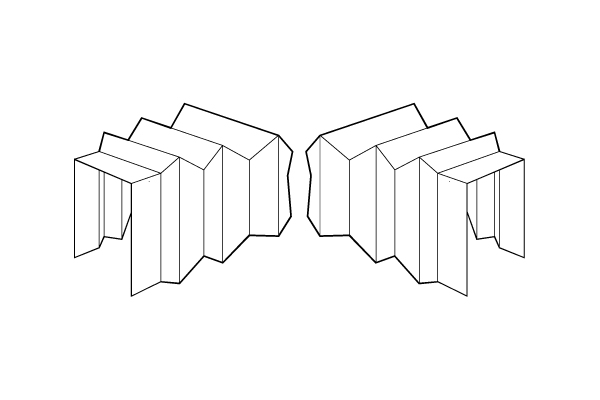

SQUARE-RECTANGULAR COLLAR/SQUARE-RECTANGULAR COLLAR

SQUARE-RECTANGULAR COLLAR/SQUARE-RECTANGULAR COLLAR SQUARE-RECTANGULAR COLLAR/SQUARE-RECTANGULAR FLANGE

SQUARE-RECTANGULAR COLLAR/SQUARE-RECTANGULAR FLANGE SQUARE-RECTANGULAR FLANGE/SQUARE-RECTANGULAR FLANGE

SQUARE-RECTANGULAR FLANGE/SQUARE-RECTANGULAR FLANGE