Electric Cylinders 2.5 Ton

ECAL242.5, ECAH62.5, ECAH122.5, ECAH242,5, ECBL62.5, ECBL122.5, ECBL242.5, ECBM62.5, ECBH62.5

These Joyce electric cylinders lift and position up to 2.5 tons, achieve travel speeds up to 291 inches per minute, and raise loads up to 44 inches. They are well suited for industrial environments where protection of the lifting screw mechanism is critical and low maintenance is desired. Requiring only electric power, Joyce electric cylinders may also be used in place of hydraulic cylinders, eliminating the cost and potential for leaks associated with hydraulic systems.

- 2.5 ton capacity and available in a variety of ratios and leads

- Standard, Motor mount, and ComDRIVE models are available

- Ground and hard-chrome plated inner tubes, alloy steel input shafts

- All models with efficiencies ≥ 30% require a brake motor to hold position

- Joyce Dayton can customize electric cylinders to your specifications

Complete dynamic speed/load ratings and maximum rise information can be viewed on our quick reference charts. Both acme (ECA) and ball screw (ECB) electric cylinder actuator models are designed to operate at the charted capacities under both tension and compression loading.

Motor Controls:

Joyce/Dayton offers motor controls ranging from simple Motor Starters to complex positioning systems and Custom controls. Every system that is powered by an electric motor requires a control system. At Joyce, we know that choosing the best option can sometimes be a challenge. That’s why our Engineers are available to help you through the process.

2D/3D Drawings

Login to access 2D/3D Drawings

Product Media

Available Models

Sample Part Number:

Click on the part number to reveal additional informaton about jack designs and shaft codes.

Model Number

| 2.5-Ton ACME Screw |

2.5-Ton Ball Screw |

3-Ton ACME Screw |

3-Ton Ball Screw |

5-Ton ACME Screw |

5-Ton Ball Screw |

10-Ton ACME Screw |

10-Ton Ball Screw |

20-Ton ACME Screw |

20-Ton Ball Screw |

|---|---|---|---|---|---|---|---|---|---|

| ECAL242.5

ECAH62.5 |

ECBL62.5 ECBL122.5 ECBL242.5 ECBM62.5 ECBH62.5 |

ECAL63 ECAL123 ECAL243 |

ECBL63 ECBL123 ECBL243 ECBH63 |

ECAL65 ECAL245 ECAM65 ECAH65 |

ECBL65 ECBL125 ECBL245 ECBM65 ECBH65 |

ECAL810 ECAL2410 ECAM810 ECAH810 |

ECBL810 ECBL2410 ECBM810 ECBH810 |

ECAL820 ECAL2420 ECAM820 ECAH820 |

ECBL820 ECBL2420 |

Important Note: Electric Cylinders that are ≥ 30% efficient may lower under load. Brake motors or external locking systems are required.

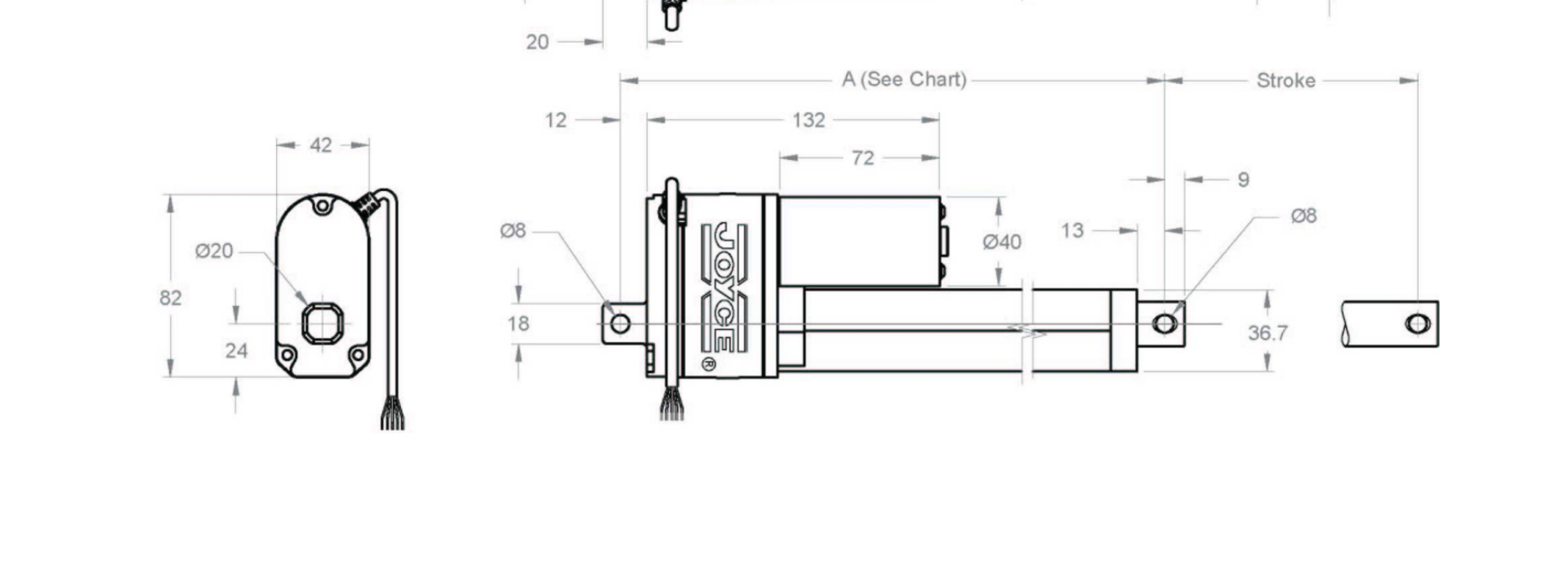

Tube End Conditions

|

|

|

|

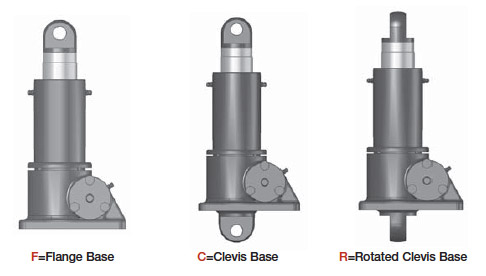

Base Designs

|

Cylinder Rise

Rise is travel expressed in inches and not the actual tube length. The allowable travel for each unit is listed in the Quick Reference section. Allowable lengths differ for vertical and horizontal mounting.

Left Side Shaft Code |

Right Side Shaft Code |

|

XXXX=Remove |

XXXX=Remove |

Optional Shaft Codes

Screw Stops and Boots

Screw stops are optional on machine screw jacks. When specified, the closed height of the jack and/or the protection tube length may be increased. When boots are added to machine screw jacks, the closed height of the jack may be increased.

Mechanical Counters

CNT0=0.001" Increments

Note: Contact Joyce/Dayton for availability and options.

Hand Wheels

HW04=4" dia

HW06=6" dia

HW08=8" dia

HW10=10" dia

HW12=12" dia

Not recommended for cylinders that are ≥ 30% efficient.

Geared Potentiometers

POTA=0-10V (IP65)

POTB=4-20MA (IP65)

POTC=0-10V w/2 switches*

POTD=4-20MA w/2 switches*

*Optional IP65 rating available

Encoders and Electronic Liit Switches

ENCX=Encoder

ELS2=2 Position Electronic Switch

ELS4=4 Position Electronic Switch

ELS6=6 Position Electronic Switch

| ComDrive Reducers | |||||

|---|---|---|---|---|---|

| Ordering Example: P2 (Moutning Positions) A (Ratio) C (Motor code from chart below) | |||||

| Mounting Positions | Ratio | ||||

| Code | P1 | P2 | P3 | P4 |

5:1 7.5:1 10:1 |

| Left Side Shaft Positions |

|

|

|

|

|

| Right Side Shaft Positions |

|

|

|

|

|

Motors

| Size | Code |

|---|---|

| 1/4 HP | K |

| 1/3 HP | A |

| 1/2 HP | B |

| 3/4 HP | C |

| 1 HP | D |

| 1-1/2 HP | E |

| 2 HP | F |

| 3 HP | L |

| 5 HP | G |

Motor Mounts

Ordering Example:

MMA A (Motor code from chart above)

MMA=56C

MMB=140TC

MMC=180TC

MMD=210TC

Standard motor adapters are aluminum

All standard motors are 3-phase, 208-230/460 VAC or 230/460 VAC. Specify the appropriate motor size from the chart above. Refer to the "Additional Options" chart on the preceding page as needed. Brake motors are required for electric cylinders that are more than 30% efficient. Contact Joyce/Dayton options that are not listed.

Mechanical Limit Switches

Ordering Example:

LA (Models) 1(Number of DPDT Switches) 3(Available Positions)

| Model | Code | Available Positions | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LS7-402 | LI |

Number of DPDT Switches NOTE: Will always be 0 for LS7 models |

1 | 3 | 5 | |||||

| LS8-402 | LA | Left Side Shaft Options |  |

|

|

|||||

| LS8-504 | LB | |||||||||

| LS9-502 | LC | |||||||||

| LS9-503 | LD | Right Side Shaft Options |  |

|

|

|||||

| LS9-504 | LE | |||||||||

| LS9-505 | LF | |||||||||

| LS9-506 | LG |

|

||||||||

| LS9-507 | LH | |||||||||

To order additional options, use these part numbers

Female Clevis Bracket

FCB-30

FCB-100

FCB-200

Clevis Pin w/ retaining rings

CP-30

CP-100

CP-200

Female Rod Clevis

FRC-30

FRC-100

FRC-200

Additional Options

- X=Standard Jack, no additional options

- S=Additional Specification Required (comment as necessary)

Finishes

- F1=Do Not Paint

- F2=Epoxy Paint

- F3=Outdoor Paint Process

Motor Options

- M1=Less Motor

- M2=Brake Motor

- M3=Single Phase Motor (120VAC)

- M4=50Hz Motor

Grease/Seals

- H1=High Temperature Operation

- H2=Food Grade

- Specify as many options as needed

| Model | Static Capacity | Screw Diameter | Thread Pitch/Lead | Worm Gear Ratio | Worm Shaft Turns for 1" Travel | Tare Torque (Inches Lbs.) | Starting Torque (Inches Lbs.) | Operating Torque (Inches Lbs.) | Translating Tube Torque (Inches Lbs.) | Base Weight | Weight per Inch Travel |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ECAL242.5 | 2.5 ton | 1 | .25 pitch ACME 2C |

24:1 | 96 | 6 | .018W* | .010W* @ 500 RPM |

.098W* | 24 | 1.5 |

| ECAH62.5 | 2.5 ton | 1 | .25 pitch .5 lead ACME 2C |

6:1 | 12 | 8 | .056W* | .040W* @ 500 RPM |

.140W* | 24 | 1.5 |

| ECAH122.5 | 2.5 ton | 1 | .25 pitch .5 lead ACME 2C |

12:1 | 24 | 7 | .035W* | .023W* @ 500 RPM |

.140W* | 24 | 1.5 |

| ECAH242.5 | 2.5 ton | 1 | .25 pitch .5 lead ACME 2C |

24:1 | 48 | 6 | .025W* | .014W* @ 500 RPM |

.140W* | 24 | 1.5 |

| ECBL62.5 | 2.5 ton | 1 | 0.25 lead ball | 6:1 | 24 | 8 | .017W* | .013W* @ 500 RPM |

.045W* | 30 | 1.5 |

| ECBL122.5 | 2.5 ton | 1 | 0.25 lead ball | 12:1 | 48 | 7 | .010W* | .008W* @ 500 RPM |

.045W* | 30 | 1.5 |

| ECBL242.5 | 2.5 ton | 1 | 0.25 lead ball | 24:1 | 96 | 6 | .008W* | .005W* @ 500 RPM |

.045W* | 30 | 1.5 |

| ECBM62.5 | 2.5 ton | 1 | 0.5 lead ball | 6:1 | 12 | 8 | .033W* | .026W* @ 500 RPM |

.089W* | 30 | 1.5 |

| ECBH62.5 | 2.5 ton | 1 | 1 lead ball | 6:1 | 6 | 8 | .065W* | .051W* @ 500 RPM |

.177W* | 30 | 1.5 |

Important Note: Electric cylinders that are ≥ 30% are not self-locking. Brake motors or external locking systems are required.

*W: Load in pounds.

Tare Torque: Initial torque to overcome seal and normal assembly drag. This value must be added to starting torque or operating torque values.

Starting Torque: Torque value required to start moving a given load (dissipates to operating torque values once the load begins moving).

Operating Torque: Torque required to continuously raise a given load at the input RPM listed.

Translating Tube Torque: Torque required to resist tube rotation.

Lead: The distance traveled axially in one rotation of the lifting screw.

Pitch: The distance from a point on a screw thread to a corresponding point on the next thread, measured axially.