Anti-backlash Devices

Anti-backlash Devices

Anti-backlash devices are internal jack components used to minimize backlash (free movement between the lifting screw and nut) in machine screw jacks. They are typically used in reversing load applications where the lifting screw position is critical. Joyce/Dayton offers three unique anti-backlash designs; each uses the same concept of clamping two independent nut halves against the lifting screw threads.

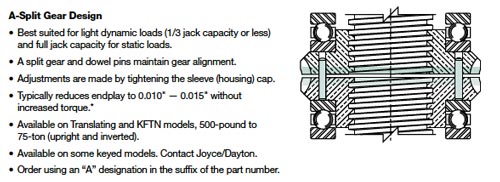

A- Split Gear Design

Best suited for light dynamic loads (1/3 jack capacity or less for dynamic loads), and full jack capacity for static loads. A split gear and dowel pins maintain gear alignment. Adjustments are made by tightening the sleeve cap. These typically reduce endplay to 0.010" to 0.015" without increased torque.They are available on translating and KFTN models, 500-pounds to 75-tons and on some keyed models.

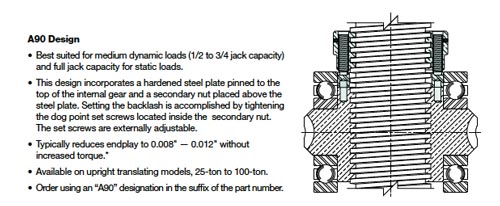

A90 Design (Shown at right)

Best suited for medium dynamic loads (1/2 to 3/4 jack capacity) and full jack capacity for static loads.This design incorporates a hardened steel plate pinned to the top of the internal gear and a secondary nut placed above the steel plate. Setting the backlash is accomplished by tightening the dog point set screws located inside the secondary nut. The set screws are externally adjustable. These typically reduce endplay to 0.008" - 0.012" without increased torque. They are available on upright translating models, 25-ton to 100-ton.

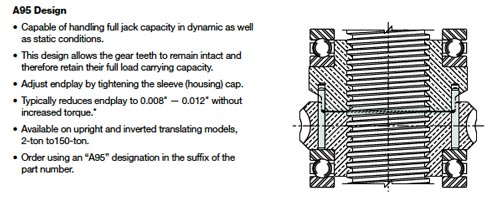

A95 Design

Capable of handling full jack capacity in dynamic as well as static conditions. This design allows the gear teeth to remain intact and therefore to retain their full load carrying capacity. Adjust endplay by tightening the sleeve cap. These typically reduces endplay to 0.008"-0.012" without increased torque. Available on upright and inverted translating models, 2-ton to 150-ton.

Ordering Information:

Since anti-backlash devices are part of the jack’s internal construction, they are specified as part of the suffix of the complete part number. Refer to the ordering section for the products on which they will be used.

Note: If the backlash is set below the recommended values, torque values will increase significantly and thread wear will accelerate.

Product Media

FAQ's

Where are anti-backlash devices used?

Anti-backlash devices are frequently used in steel mill applications where the screw jacks are used to set and maintain the position of the movable upper roll of a rolling mill. In operation, the initial weight of the roll pulls the lifting screw to the upper or lower edge of the nut. When steel passes through the rolls, the load reverses on the lifting screw and the anti-backlash device limits movement in the opposite direction. Other common applications include screw jacks used to position communication antennas and solar panels. In these applications, directional changes in the wind can buffet the panels thus affecting the position of the lifting screw. During these high wind conditions, anti-backlash devices minimize the lifting screw movement.

Will the anti-backlash device require adjustment?

When the internal nut threads begin to wear, lifting screw backlash increases. Subsequent adjustment of the anti-backlash device compensates for the nut wear and allows the user to limit the backlash to the recommended value. Adjustment frequency will vary depending on load, duty cycle, and temperature. The anti-backlash device should be replaced when no further adjustment is possible due to thread wear.

What effect do anti-backlash devices have on torque requirements?

Torque requirements for screw jack operation are affected by the clearance between the lifting screw and nut thread. Adjusting anti-backlash devices (within recommended values for each design) will not increase the torque to move a given load. If the backlash is set below the recommended values, torque values will increase significantly and thread wear will accelerate.

Can anti-backlash devices be used on ball screw jacks and bevel ball actuators?

No. Rather, the use of oversized ball bearings in translating ball nut assemblies or preloaded ball nuts in KFTN assemblies is recommended to reduce endplay in the ball screw jacks and bevel ball actuators.

Aluminum bronze internal nut.