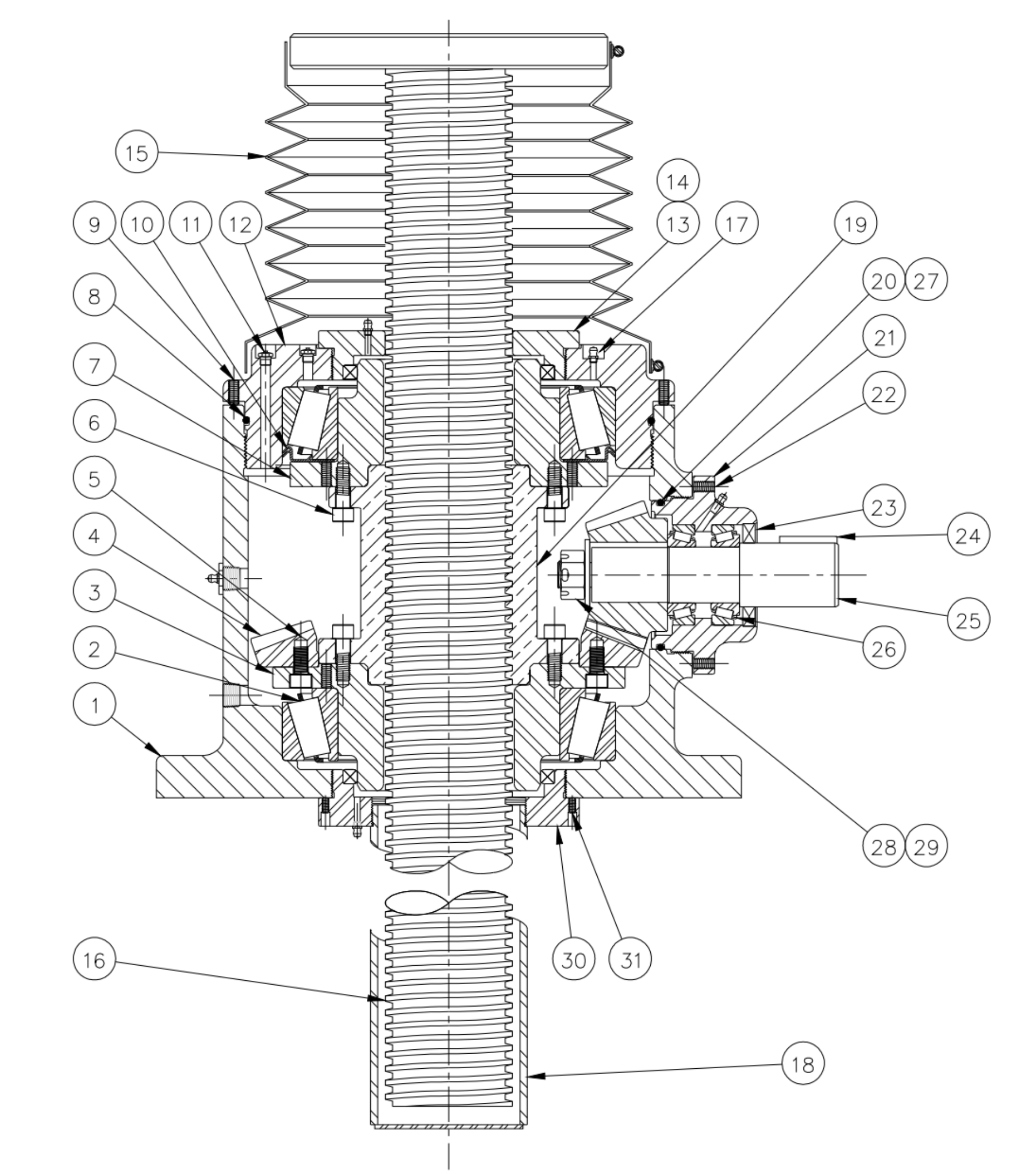

Bevel Ball Jacks

About Bevel Ball Jacks

Joyce Bevel Ball Actuators (BB), available in 7.5-ton to 100-ton static capacities, are designed for near-continuous duty operation. These are Joyce’s fastest jacks, able to attain travel speeds of 48.6 feet per minute. Available in Translating and KFTN designs, bevel ball actuators act as miter boxes, making them an ideal choice for multi-jack systems. As many as three output shafts may be specified for mounting motors, limit switches, readout devices and other accessories.

- Higher speeds and less heat generation than other mechanical actuators

- Require a brake or other external locking device to hold position

- More precise positioning and repeatability than hydraulic cylinders

- Fully predictable J-10 ball nut life expectancy

- Right hand screws standard (left hand screw available)

- Threaded end conditions standard (load pad, clevis, and plain end condition available)

- Protective boots and other options are available

Product Media

Joyce offers motor controls ranging from simple Motor Starters to complex positioning systems and Custom controls. Every system that is powered by an electric motor requires a control system. At Joyce, we know that choosing the best option can sometimes be a challenge. That’s why our Engineers are available to help you through the process.

Available Models

Ball Screw Options

- Right hand thread standard

- Left hand thread available on many models

- Special pitch/lead available

- Special finishes available

- Special machining options

Encoders

- Standard 200 or 1024 PPR

- Quadrature wave form

- Stainless steel encoder

- Absolute encoder

- Encoders

Finishes

- Enamel finish (standard)

- Epoxy finish

- STEEL IT® epoxy

- Outdoor paint process

- Custom finishes available

- Anodized (250-lb to 1-ton)

- Nickel, Xylan®, Armoloy®

- Finishes

Limit Switches

- Rotary cam (2-4 switches)

- SPDT standard

- DPDT available

- Explosion proof available

- Limit Switches

Lubrication

- Standard grease temperature range (40°F to 220°F)

- Low temperature option

- High temperature option

- Food grade option

Oversized Ball Bearings

- Available for ball screw jacks

- Limits screw backlash to 0.003"

Protective Boots

- Protection from dirt and dust

- Guard against moisture

- Guard against corrosive contaminants

- Neoprene coated nylon (std)

- Special materials available

- Boot Material Chart

- Protective Boots

Screw Stops

- Standard on ComDRIVEs

- Adjustable

- Bolt- on

| Model | Dynamic Capacity | Upright Assembly: Screw-in tension | Upright Assembly: Screw-in compression | Screw Dia./Lead | Bevel Gear Ratio | Pinion Turns for 1" Travel | Pinion Torque (Raising) | Pinion Torque (Holding) | Screw Torque | Actuator Efficiency | Base Weight (Lbs.) | Add for Each Inch of Travel (Lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BB150 | Please use JAX® V2 software or contact Joyce/Dayton | 15,000 lbs. | 15,000 lbs. | 1.50/.25 | 2.69:1 | 10.77 | .022W* | .018W* | .044W* | 72.2% | 52 | 0.7 |

| BB225 | 30,000 lbs. | 30,000 lbs. | 2.25/.50 | 2.15:1 | 4.31 | .054W* | .044W* | 089W* | 200 | 2.6 | ||

| BB300 | 42,500 lbs. | 70,000 lbs. | 3.75/.66 | 3.52:1 | 5.34 | .044W* | .035W* | .117W* | 360 | 3.2 | ||

| BB400 | 200,000 lbs. | 200,000 lbs. | 4.00/1.00 | 3:1 | 3.00 | .078W* | .063W* | .117W* | 740 | 4.8 | ||

| Inverted Assembly: Screw-in tension | Inverted Assembly: Screw-in compression | |||||||||||

| BB150 | Please use JAX® V2 software or contact Joyce/Dayton | 15,000 lbs. | 15,000 lbs. | 1.50/.25 | 2.69:1 | 10.77 | .022W* | .018W* | .044W* | 72.2% | 52 | 0.7 |

| BB225 | 30,000 lbs. | 30,000 lbs. | 2.25/.50 | 2.15:1 | 4.31 | .054W* | .044W* | 089W* | 200 | 2.6 | ||

| BB300 | 70,000 lbs. | 42,500 lbs. | 3.75/.66 | 3.52:1 | 5.34 | .044W* | .035W* | .117W* | 360 | 3.2 | ||

| BB400 | 200,000 lbs. | 200,000 lbs. | 4.50/1.00 | 3:1 | 3.00 | .078W* | .063W* | .117W* | 740 | 4.8 |

Important Note: *Not self-locking, may lower under load. Brake motors or external locking systems are recommended.

D: Double Lead Screws.

S: Single Lead Screws. These jacks are self-locking.

*W: Load in Pounds.

Pinion Torque: The torque required to continuously raise a given load.

Screw Torque: The torque required to resist screw rotation (translating jack design) and traveling nut rotation (keyed for traveling nut design).

Lead: The distance traveled axially in one rotation of the lifting screw.

Pitch: The distance from a point on the screw thread to a corresponding point on the next thread, measured axially.

†: Cooling time based on time to cool from 200°F to 70°F (ambient).